Sunlite® Multiwall

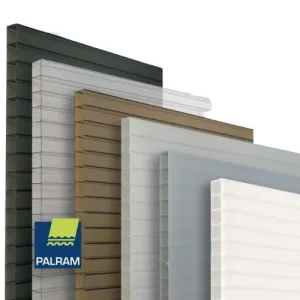

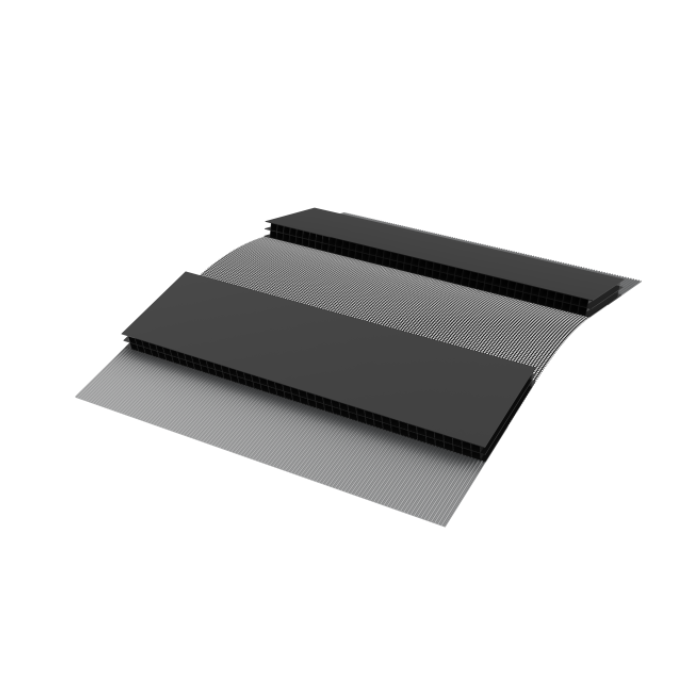

Residential and DIY Multiwall & Twin wall Polycarbonate Roofing Sheets

Enjoy natural daylight with optimal thermal performance and style. Upgrade your outdoor living space with SUNLITE DIY multiwall polycarbonate. SUNLITE DIY is easy to install and handle for any remodeling project.

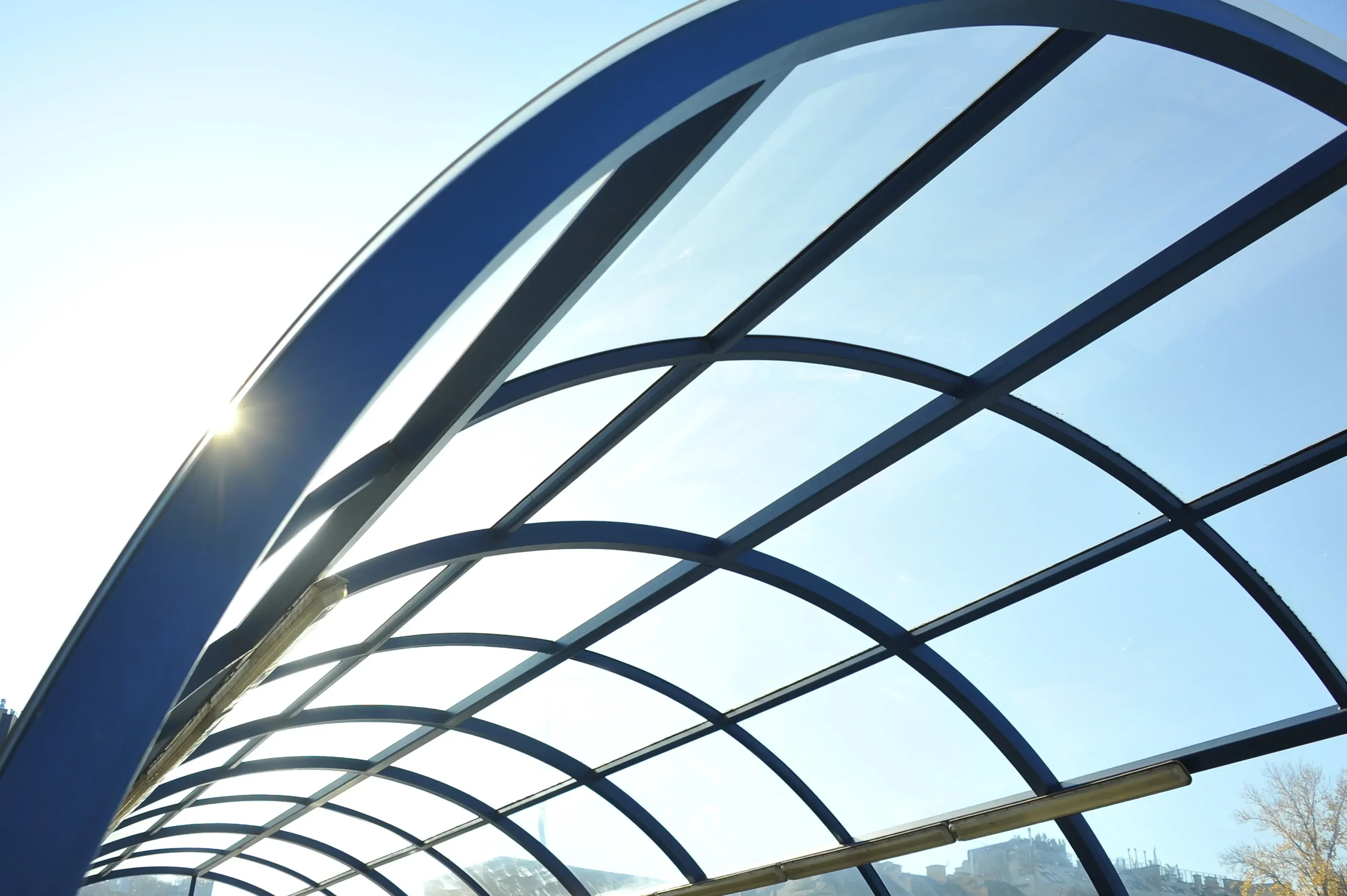

A dream solution for clear patio roofs, privacy partitions, DIY skylights, covered pergolas, covered carports, hobby greenhouses, and more.

UV protection keeps the panel itself and everything underneath safe. Choose from clear or colored polycarbonate sheets. Make your home bright and comfortable all year long with natural daylight.

Benefits

Lightweight & easy to install

Hail & impact resistant

For every budget & application

Protects against UV radiation

Balance shade & daylight

10 years warranty

Applications

Our Products

Sunlite 10mm Twinwall Polycarbonate

FAQ

To curve polycarbonate sheets, first, ensure they are heated gently using a heat gun or warm air to make them pliable. Then, carefully shape the material over a form that matches the desired curve, ensuring you maintain uniform pressure. Allow the polycarbonate to cool and set in place to maintain the curve.

The thickness of polycarbonate should be chosen based on structural requirements, the span of the installation, and local climate conditions. Generally, for roofing and façades, thicker sheets (4mm or more) are recommended for better impact resistance and insulation. Consult with an engineer for specific applications.

To minimize heat build-up, consider using polycarbonate sheets with a high solar heat gain coefficient (SHGC). Additionally, integrating reflective coatings or shades can help deflect sunlight. Ventilation options, such as operable windows or roof vents, can also enhance airflow and reduce heat retention.

The minimum bending radius for polycarbonate is typically 150 times the thickness of the sheet. For example, a 4mm thick sheet would have a minimum bending radius of 600mm. Always consult the manufacturer's specifications for precise guidelines.

To install corrugated polycarbonate sheets as a skylight, start by securing the framework. Ensure that the sheets are cut to the correct length and aligned with the ridge and eave. Use appropriate fasteners, ensuring they are installed in the valley of the corrugation to prevent leaks. Seal all joints and edges with compatible sealant to enhance waterproofing.

The “UV-side” is treated to enhance its UV protection and durability. It is designed to face outward to block harmful UV rays while allowing visible light to pass through. This treatment helps prolong the life of the material and protects against yellowing and degradation.

Pre-drilling fastener holes prevents cracking and ensures proper sealing. It allows for thermal expansion and contraction of the panels without stress, helping maintain the integrity of the roofing system and reducing the risk of leaks.

Polycarbonate is designed for durability, but prolonged exposure to UV rays and environmental factors can lead to some deterioration of light transmittance over time. Choosing high-quality materials and protective coatings can help mitigate this issue.

To determine these properties, refer to the product specifications provided by the manufacturer. Light transmission can be tested using a photometer, while haze is assessed using a haze meter. For color, physical samples are available, allowing you to see how the polycarbonate will look in your application.